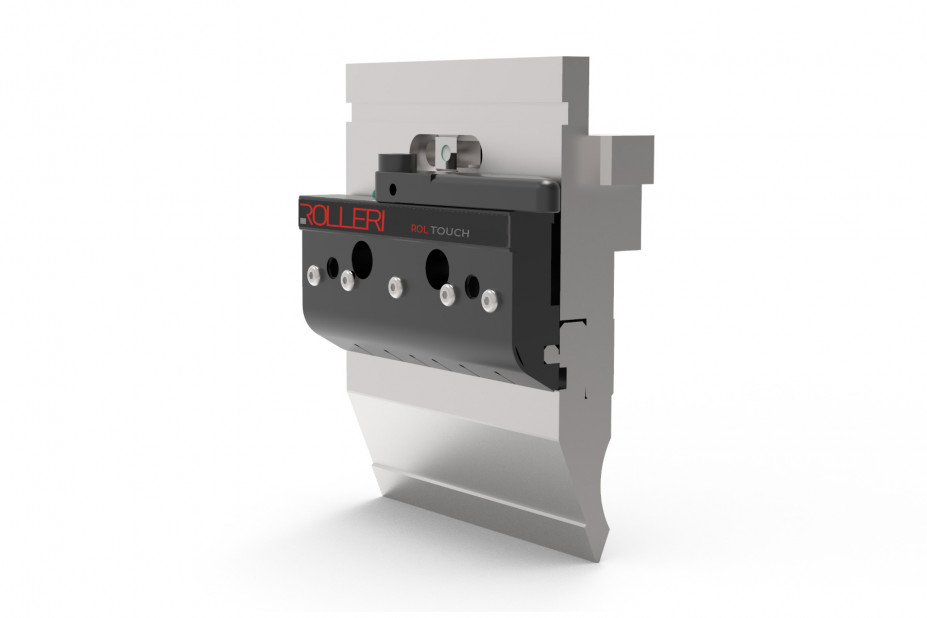

ROL TOUCH

(excluding packaging and transport)

Thanks to ROL TOUCH clamp you can keep the intermediates on your press brake, and replace only front clamp: a fast-clamping system with a small investment.

Vertical tool change for standard European type punches and automatic alignment.

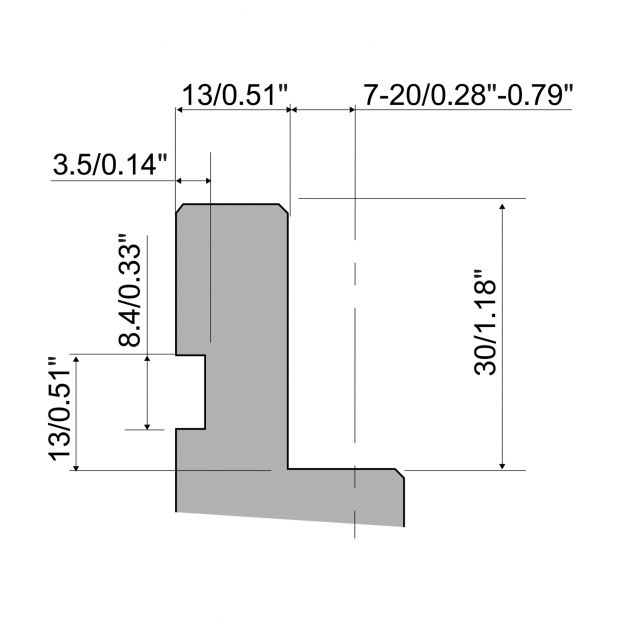

| Article No. | Type | Price | |

|---|---|---|---|

| ST ROL TOUCH 7 H40 | ROL TOUCH clamp for intermediate H=40mm axis 7mm |

|

|

| ST ROL TOUCH 7 H39 | ROL TOUCH clamp for intermediate H=39mm axis 7mm |

|

|

| ST ROL TOUCH 20 | ROL TOUCH clamp for intermediate axis 20mm |

|

- Description

- Features

Manual clamping for punches with ergonomic lever. Compatible with all press brakes with Amada-Promecam type tang.

Set-up time

| OPERATION | TRADITIONAL MODEL MANUAL WITH SCREWS | MODEL TEDA SPEED GRIP MANUAL (13131-M) |

|---|---|---|

| Screws loosening | 30 screws = 5″ total = 150″ |

15 modules by lever = 2″ total = 30″ |

| Tool extraction | Lateral = 25″ total = 100″ |

Frontale = 8″ total = 32″ |

| Tool loading | Lateral = 25″ total = 100″ |

Lateral = 6″ total = 24″ |

| Pre-screwing 30 screws | 4″ total = 120″ |

– |

| Light pressing to house tools | 10″ total = 10″ |

– |

| Screws tightening 30 screws | 3″ total = 90″ |

– |

| Clamping 15 modules by ergonomic screw | – | 4″ total = 30″ |

| TOTAL TIME | 570″ = 9′,30″ | 116″ = 1′,56″ |