RVM70-3_12.7

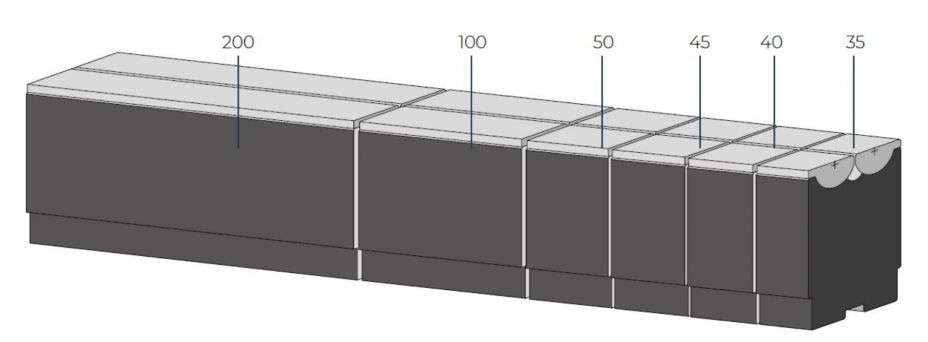

Rolla-V die with 12.7mm milled groove. RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 47°.

RVM2.5TOOLS > PRESS BRAKES > Rolla-V > RVM2.5_12.7RVM2.5_13

| Article No. | Model | Length | Weight | Price | |

|---|---|---|---|---|---|

| RVM2.5.500.12,7 | 2.5 | 500 mm | 23.5 |

|

|

| RVM2.5.470s.12,7 | 2.5 | 470 mm F | 22.4 |

|

|

| RVM2.5/SP.12,7 | Spring |

|

|||

| RVM2.5/IN.12,7 | Insert |

|

|||

| RVM2.5/DO.12,7 | Dowel |

|

|||

| RVM2.5/U.12,7 | U clip |

|

Rolla-V die with milled groove 12,7 x 19 mm. RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 46°.

Rolla-V die with 12.7mm milled groove. RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 47°.

Rolla-V die with milled groove 13 RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 47°.

Rolla-V die with 60 mm base. RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 47°.

Rolla-V die with milled groove 12.7 x 19 mm. RVM series in 42 Cr. Max.load 3000 kN/m. Minimum angle 73°.

Rolla-V die with milled groove 13 x 20 mm. RVM series in 42 Cr. Max.load 3000 kN/m. Minimum angle 73°.

Rolla-V die with 60 mm base. RVM series in 42 Cr. Max.load 3000 kN/m. Minimum angle 73°.

Rolla-V die with milled groove 13 RVM series in 42 Cr. Max.load 2500 kN/m. Minimum angle 47°.

Rolla-V die with milled groove 13 x 20 mm. RVM series in 42 Cr. Max.load 3000 kN/m. Minimum angle 73°.