How to prevent galling?INFORMATION > TIPS AND INFORMATION > Punching thicker material ( <3~4mm MS / <2~3mm SS)Punching non-metallic or plastic materials

Punching thicker material ( <3~4mm MS / <2~3mm SS)

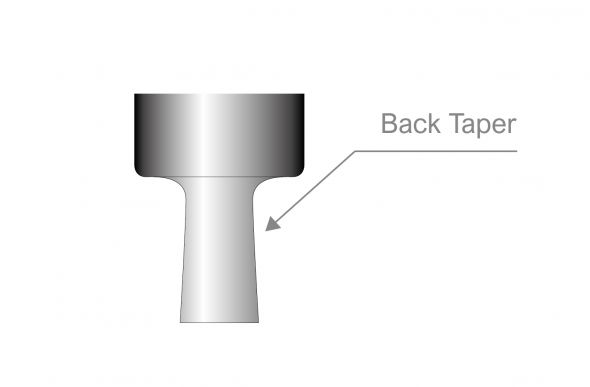

Extra Back Taper on the punch tip - 0.5 ° per side (standard 0.2 ° per side)

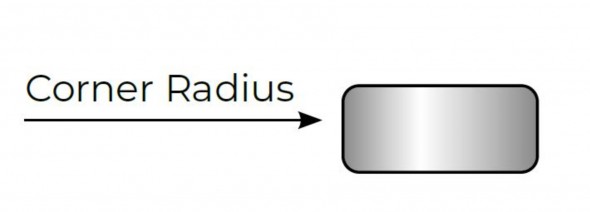

Corner radius - 0.5mm C.R. on shaped punch (Min.)

- Sharp punches and dies;

- Multiply the standard game x 1.4;

- Extra Back-taper on the punches;

- Ratio between diameter min. punch and material thickness of at least 1.5 ~ 2;

- Check the wear of tools often;

- Lubricate the plate, punch and guide;

- Make the machine work slower;

- Use heavy duty tools (if available);

- Check if the tool holder springs are in place;

- Use a larger station with special tools.