Up-Grind and tool sharpening service

Tools sharpening can give back to a punch all features as first purchased, but the machine that should be used for regrinding tool is also very import…

ROLLA-V DiesINFORMATION > TIPS AND INFORMATION > Are your tools sharpened?How to prevent slug pulling?

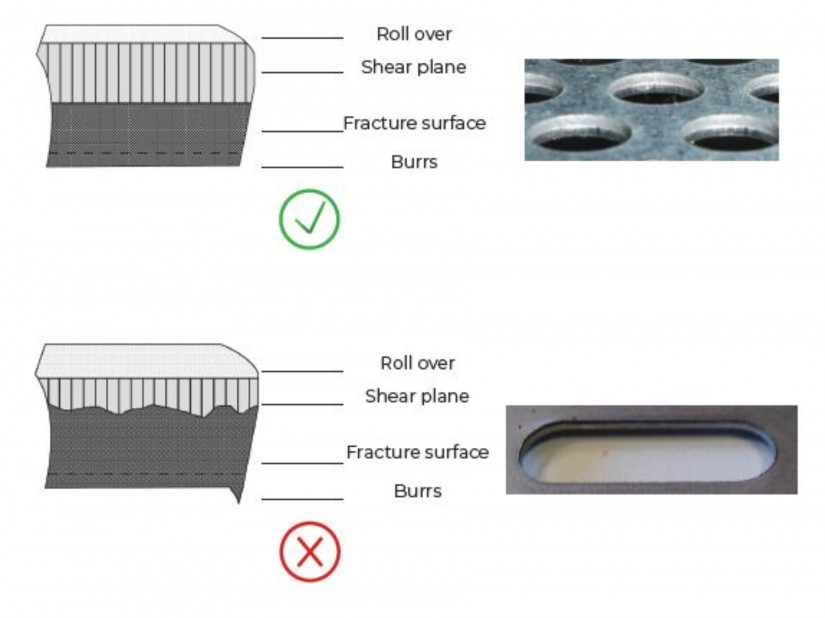

WHEN TO REGRIND: 3 BASIC INDICATORS

Tools sharpening can give back to a punch all features as first purchased, but the machine that should be used for regrinding tool is also very import…