Rolleri Tools modification

MODIFIED TANGS

Rolleri Punches Type R1, R2, and R3 can be used on other press brake machines by modifying the tang

- Precision ground (Tolerance of +/-0.01 mm)

- Exact parallelism

R1 PUNCHES

R2 PUNCHES

R3 PUNCHES

V-opening modifications

Modifying the V-Opening

- Individual modification for dies

- Production according to your specifications

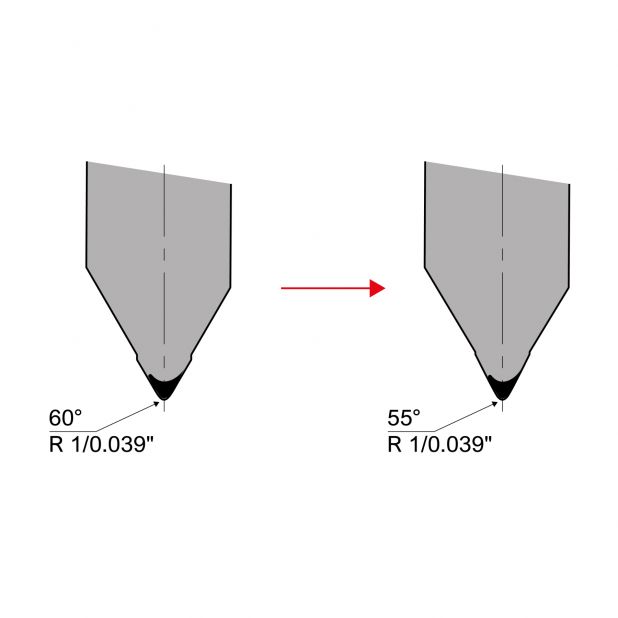

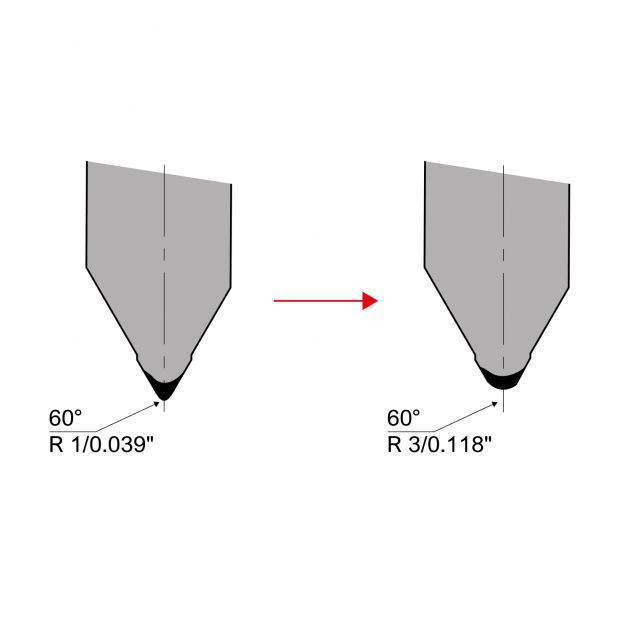

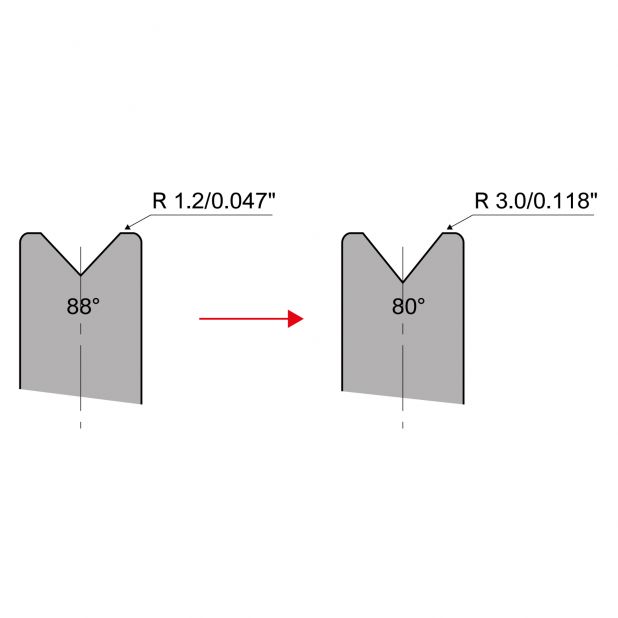

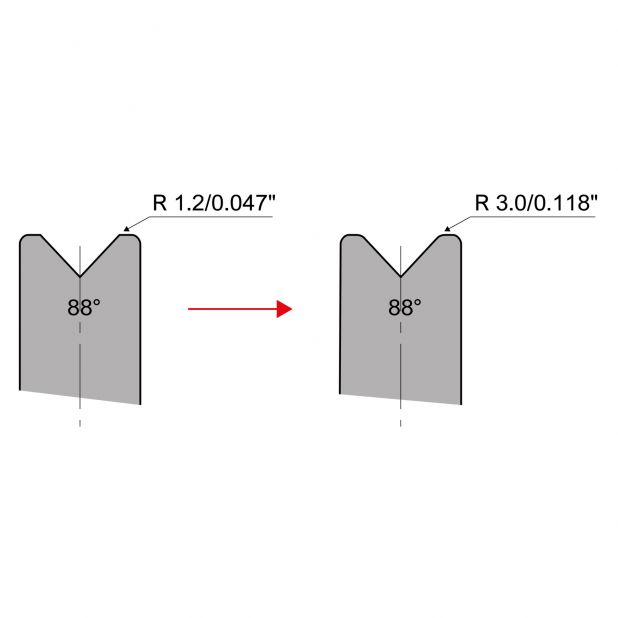

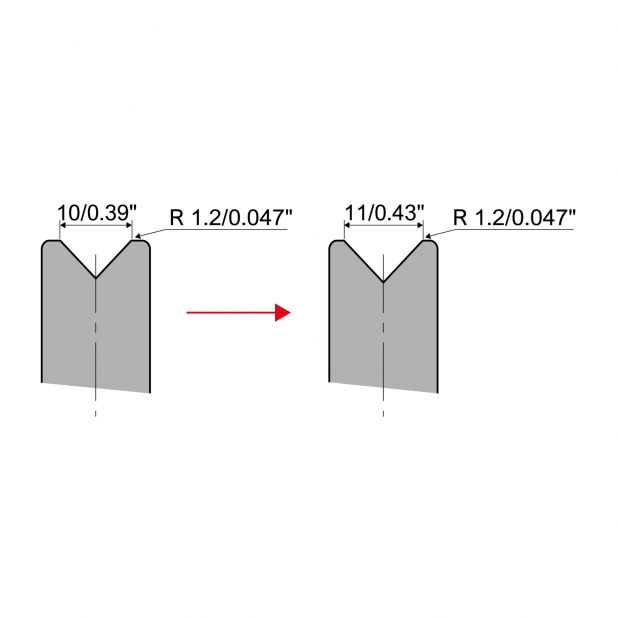

Radius and angle modification

Rolleri offers the possibility to modify tools radius and angle . For the punch it is important, for some applications, to be able to increase the radius for a better distribution of the pressure and avoid a too marked incision inside the sheet. For dies, the possibility of increasing the radius on of the V means not marking the sheet on the outside. Furthermore, for a better management of the bend and the elastic return it is possible to vary the angles of the punch and the die.

Production according to your specifications.

Modified tangs

Rolleri can mill a groove in the die base and insert a bar of the correct dimensions to use the die in a different clamping system. To avoid making special dies, thanks to this application we transform all R1 dies into tools with other tangs. A groove is milled on the die and a bar is mounted, corresponding to the attachment of the lower table. The die is perfectly aligned and looks like a monolithic piece.

Grooves for Dies

Milling of grooves to use in other press brakes