How to have more resistant tools?

Tooling durability effects a lot productivity and costly.

Rolleri present a solution to make tooling life extremely longer, SDP:

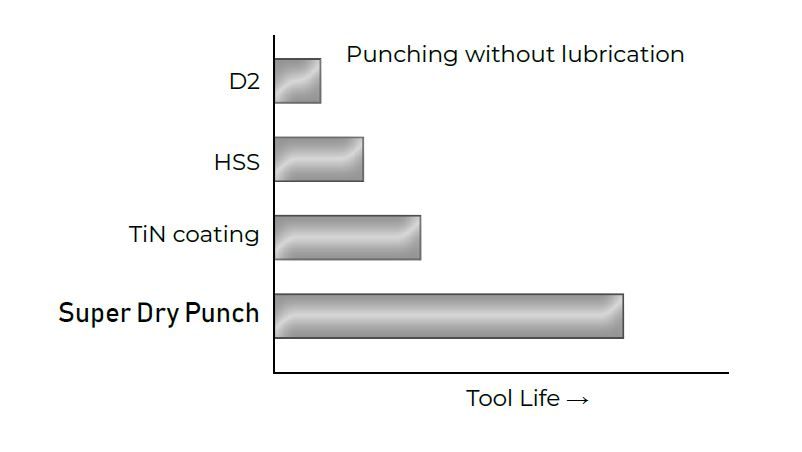

• It works extraordinary well for Stainless Steel and Mild Steel without any lubricating.

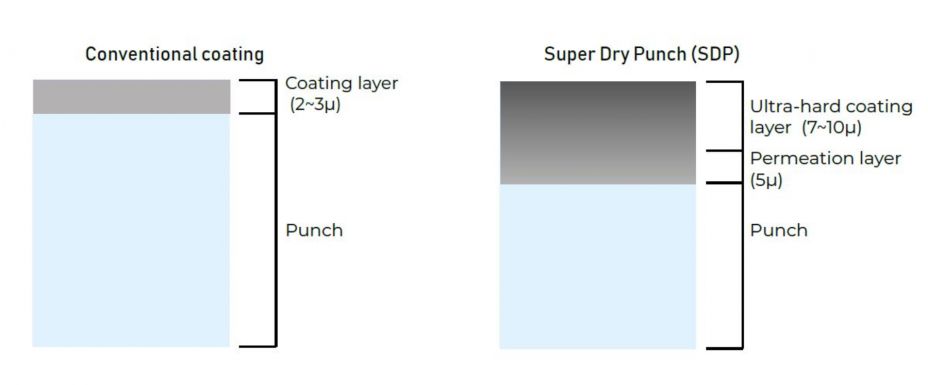

• Hardness of SDP punch is Hv2500 to 3000 and it penetrate to the HSS material.

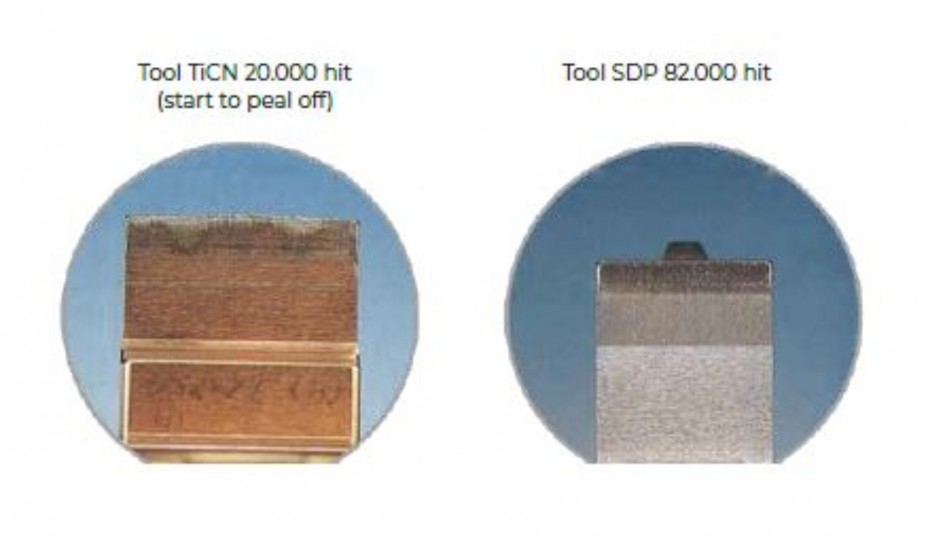

• Since it is penetrated, it won’t peel off, such as usual coating, TiN or TiCN.

According to the trial punching test SDP shows incredible durability and it is better than any other

usual coating.

- Process made in EDM that adds Titanium to the punch;

- It does not peel like conventional coatings;

- Very suitable for punching stainless steel;

- Very suitable for important thicknesses;

- Very suitable for processing without sheet metal lubrication;

- The tool life is at least 4 ~ 6 a standard tool (HSS-M2);

- Available on Round, Buttonholes, Square and Rectangular shapes (max corner radius 10mm);

- Not recommended for use on aluminum.

Comparison TiCN and SDP

- Punch Style and size: MURATA WIEDEMANN, SQ 20x20 mm

-

Material and test type: Stainless Steel 2mm, Rolleri R&D Center